Outsourcing Manufacturing: Pros & Cons You Should Know

- Date:

- Author: SVI Content Team

- Share:

Outsourcing manufacturing has become a crucial consideration for companies aiming to optimize operations and enhance efficiency. Outsourcing, the practice of entrusting manufacturing processes to external partners, offers a wide variety of advantages and drawbacks that demand careful evaluation.

In this blog, we’ll break down the benefits of outsourcing manufacturing, such as cost reduction to global market expansion. Yet, amidst the opportunities lie challenges, including quality control problems, transparency lack, etc. Without further ado, let’s unravel the pros and cons of this strategic business choice.

Part 1. Why Do Companies Outsource Manufacturing

More and more enterprises are opting for the strategy of production outsourcing under the tension of the supply chain.

What Is Manufacturing Outsourcing?

Outsourcing manufacturing, simply put, is a way for enterprises to outsource their non-core business to an external company and focus on their core business. These companies are often overseas or in a different region to produce all or part of your products instead of doing it in-house.

The traditional business model of supply, production and sales as a whole is now less favorable because it takes a lot of time to excel in each field. Under increasing global competition, you will need to focus on the development and management of the core business to improve the core competitiveness of enterprises.

And outsourcing production is a good way to make up for the shortcomings by utilizing external resources to cut down the operation and production costs

What Issues Push Companies to Outsource?

There are several triggers:

- High local labor costs for production

- Insufficient internal production capacity

- Lack of manufacturing knowledge or resources

- Strategic choices for market entry

- Risk control for supply chain volatility

If you cannot meet the demand by yourself or want to increase profits, this could be a great move for you to improve your operation without losing control.

Part 2. What Are the Benefits of Outsourcing Manufacturing

Now that we’ve explored why companies opt for outsourcing. Next, we will discuss the pros it brings to a company’s development.

1. Lower the Costs

The first thing that comes to our mind is reducing manufacturing costs. Manufacturing outsourcing delegates some of the operations to sourcing agents that are responsible for the process of production, production factories, product inspection, transportation, etc.

Many Asian countries offer lower material and labor costs, so your overall production becomes more affordable when compared to the traditional business model. You can keep product prices competitive while improving your profit margins. This helps you open the door to exploring new projects and developing the business.

2. Accelerate Core Business Competencies

With an excellent and specialized sourcing agent, you spend less time on finding and evaluating the right factory. The partner will take care of your requirements and select a suitable manufacturer on your behalf.

By outsourcing simple, non-core tasks, you can free up internal resources to focus on what you do best, such as concentrating on high-value-added and strategic businesses that grow your business faster.

3. Get Help from Professional Skills and Expertise

Reaching a skilled capability is one of the benefits of outsourcing manufacturing. Compared to experienced companies, start-ups and smaller companies often intend to deal with the personnel shortage and lack a seasoned team.

Many manufacturers specialize in certain product categories. They know how to meet quality standards, follow regulations, and solve production issues. By outsourcing, you can access professionals who can handle the challenges from production to shipment.

4. Increase the Flexibility

Outsourcing gives you the power to adjust production based on market needs. Whether you’re scaling up for peak season or scaling down to cut costs, your supply chain stays flexible.

At the same time, your internal team isn’t overloaded with low-value tasks, so they can move faster and stay focused.

5. Reduce the Risk of Recruiting Personnel

For teams or firms engaged in seasonal production that require specialized skills and production, outsourcing manufacturing to Mexico, Vietnam, or other countries is a strategic move.

If you produce in-house, every new project means more hiring, training, and equipment. That’s expensive and risky. However, with outsourcing manufacturing to countries like China and Vietnam, you pay only for what you produce.

Not only does it bypass the need to recruit new members for temporary projects, effectively lessening the strain on employee flexibility and increasing stability, but it also reduces the risk of labor disputes and increases overall operational resilience. More importantly, it allows you to spread manufacturing across different regions, which is advantageous when supply chain disruptions hit.

6. Entry into New Markets

Opening up the Global market is another pro of manufacturing outsourcing. Outsourcing allows for customization and adaptation of products to meet the specific demands and preferences of local markets. This localization can enhance product relevance and acceptance globally.

For a developing enterprise, it facilitates entry into new markets by aligning production with local regulations and preferences. This expansion contributes to the growth of the company’s global footprint.

Part 3. What Are the Challenges of Outsourcing Products

Meanwhile, when peering at the upsides of outsourcing in manufacturing industry, it is essential to evaluate its challenges.

1. Quality Control Challenges

Outsourcing means less effective monitoring of overseas manufacturing. As you relinquish direct control, it’s harder to keep an eye on quality and maintain a thorough understanding of every detail.

Solution: It’s critical to place a heightened emphasis on clearly specifying your requirements when outsourcing. Given the possibilities for uncertain quality issues throughout the process, ask for regular quality checks throughout production.

If possible, assign someone who understands your product to oversee the process or hire a local quality control team.

2. Lack of Transparency & Accountability

In the absence of transparent performance metrics, it becomes challenging to assess the outsourcing partner’s effectiveness. Poor performance may go unnoticed, leading to suboptimal outcomes and potentially affecting the outsourcing operation’s competitiveness. Moreover, the lack of accountability can hinder problem resolution and erode trust between the outsourcing agent and its partner.

Solution: Setting up a clear process for approvals, updates, and problem-solving is a practical way. And it’s important to define roles, timelines, and expectations clearly from day one.

3. Longer Lead Times

Overseas production often involves longer shipping timelines. You could encounter different issues during the production stages. If suppliers miss a deadline or customs slow things down, you might face delays.

Solution: To ensure on-time delivery, always plan ahead and build in extra time, and know the full lead time of your products. Make sure suppliers are transparent about their capacity and timelines before placing large orders. It is great to have regular follow-ups during the process from time to time.

4. Potential Intellectual Property Loss

Among the challenges of manufacturing outsourcing services, this should be solved primarily. When you’re outsourcing production, there is the unavoidable thing that some confidential information will be exposed to the outsourcing company. In some regions, protecting your intellectual property can be tricky.

Solution: To protect your business, ensure that both sides are on the same page about what info is shared, and sign contracts like NDAs (non-disclosure agreements) that impose hefty financial penalties if anyone leaks sensitive information.

5. Communication Difficulties

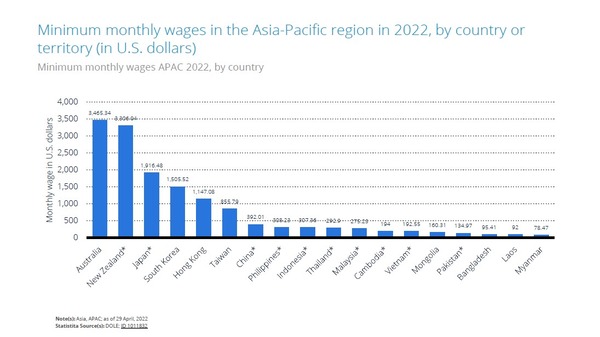

Picking a spot where resources don’t cost an arm and a leg is usually a must for saving bucks. As per recent research, Asian countries are in the limelight for low monthly wages, which are an option to choose manufacturers.

But here’s the hitch–language can be a real problem, not to mention time zones and cultural gaps. All these things can mess with your project’s schedule. If your supplier doesn’t fully understand your product requirements, mistakes can happen.

Solution: Pulling off a smooth operation requires the staff from both sides to communicate effectively and respect each other. To prevent issues, keep your communication simple, clear, and well-documented. If possible, use drawings, tech packs, and reference photos to back up your words.

Part 4. Strategies on How to Outsource Manufacturing Successfully

Once you’ve weighed the pros and cons, the next step is to approach outsourcing the smart way. Here are key strategies to help you build a strong, effective outsourcing setup:

- Define Clear Product Requirements: Make sure your product details are 100% clear, including drawings, specifications, materials, packaging and more.

- Choose the Right Sourcing Partner: Work with a reliable sourcing company that has experience in your industry, and proven track record and strong networks.

- Vet Your Manufacturers Thoroughly: Don’t go with the first factory you find. Request samples, visit the facility, check certifications, and verify experience in your product category.

- Start with a Test Order: Start with a smaller test run. This allows you to check quality, timelines, communication, and reliability. It’s also a good way to build a relationship with your new supplier.

- Use Contracts and NDAs: Always protect your business. Sign a clear manufacturing agreement and an NDA to protect your intellectual property and sensitive designs.

- Establish a Quality Control Process: If you want issues to be caught early to avoid losses, set up checkpoints for quality control during and after production.

Final Thoughts

Before embarking on the outsourcing journey, it is vital for any company to have a comprehensive understanding of the pros and cons of outsourcing manufacturing. Assessing the benefits and potential risks is necessary to make informed decisions tailored to your business needs. It continues to be a trend to opt for outsourcing, which offers advantages in areas such as cost management and business operations. However, it is imperative to remain vigilant about hidden issues like intellectual property concerns and challenges in quality control, requiring meticulous attention and positive measures.

Source Products with SVI Global

If you wonder how to outsource manufacturing, selecting the right sourcing agent holds the utmost importance. SVI Global, backed by a well-experienced team, stands as a reliable partner. It provides ultimate support for sourcing, manufacturing, quality control and product development. With SVI Global, you have a dedicated ally committed to the success of your outsourcing endeavours. Feel free to contact us and learn more!