OEM vs ODM in Manufacturing: Pros, Cons & Key Differences

- Date:

- Author: SVI Content Team

- Share:

As global trade expands, companies face increasing pressure to cut costs, speed up production, and reduce risks. For many importers and brand owners, outsourcing through OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) has become a key strategy. Both models offer unique advantages, but they also differ in cost, customization, lead time, and responsibility.

So, what’s the real difference between OEM vs ODM? And more importantly, which model is the best fit for your business goals? In this guide, we’ll break down how OEM and ODM work, compare their pros and cons, and help you make a decision on which path to take for your sourcing strategy.

Part 1. OEM vs ODM: What Do They Mean & Examples

✔ OEM – Original Equipment Manufacturer

In the manufacturing industry, OEM stands for “Original Equipment Manufacturer,” which refers to a factory that has the equipment and capacity for mass production and often provides after-sales support. The core competitiveness of OEM lies in its precise, reliable production, rather than its design capabilities.

The buyer needs to provide product design, prototype, technical specifications, and production requirements. Some clients may even designate suppliers or directly provide molds, testing tools, and raw materials required.

The factory’s role is to strictly follow these instructions exactly and produce goods that carry the buyer’s brand name only.

OEM factories are vital for global trade, especially in developing countries like China, Vietnam, and Indonesia, where they drive growth by learning advanced techniques while serving international brands.

📌 OEM Example

You create a detailed T-shirt design, including fabric, size, and color specifications.

Then, you partner with an OEM garment factory that handles cutting, sewing, and finishing the shirts according to the provided artwork.

The finished products are labeled with your brand and delivered to the required destination.

So basically, OEM = you design, they produce.

✔ ODM – Original Design Manufacturer

ODM stands for “Original Design Manufacturer” in international trading, which means a supplier that not only manufactures goods but also designs and develops them.

Buyers can directly select from the existing product design plans provided by ODM. With minor modifications (like color changes, logo placement, or small functional adjustments), the products can be rebranded and sold under the buyer’s name.

Compared with OEM, ODM suppliers offer higher technical expertise and faster time-to-market since buyers don’t need to invest heavily in design or product development.

📌 ODM Example

You want to sell T-shirts, but you only get rough ideas or don’t know how to design them.

You find an ODM garment supplier and pick one style from its 100 pre-designed T-shirt styles, add your brand logo, make some tweaks, and start selling immediately.

All in all, ODM = they design + produce, you brand.

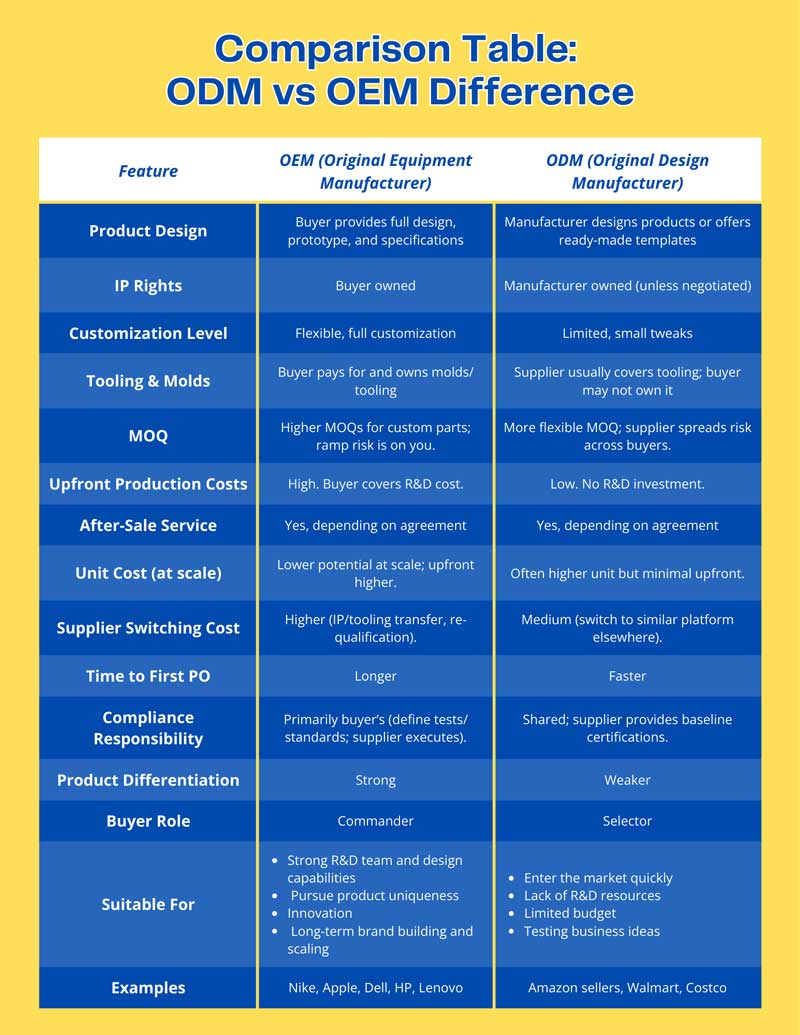

Part 2. Comparison Table: ODM vs OEM Difference

1) Product Design

– OEM: Buyer provides full design, prototype, and specifications

– ODM: Manufacturer designs products or offers ready-made templates

2) IP Rights

– OEM: Buyer owned

– ODM: Manufacturer owned (unless negotiated)

3) Customization Level

– OEM: Flexible, full customization

– ODM: Limited, small tweaks

4) Tooling & Molds

– OEM: Buyer pays for and owns molds/tooling

– ODM: Factory usually covers tooling; buyer may not own it

5) Minimum Order Quantity (MOQ)

– OEM: Higher MOQs for custom parts; ramp risk is on you.

– ODM: More flexible MOQ; supplier spreads risk across buyers.

6) Upfront Production Costs

– OEM: High. Buyer covers R&D cost.

– ODM: Low. No R&D investment

7) After-Sale Service

– OEM: Yes, depending on agreement

– ODM: Yes, depending on agreement

8) Unit Cost (at scale)

– OEM: Lower potential at scale; upfront higher.

– ODM: Often higher unit but minimal upfront.

9) Supplier Switching Cost

– OEM: Higher (IP/tooling transfer, re-qualification).

– ODM: Medium (switch to similar platform elsewhere).

10) Time to First PO

– OEM: Longer

– ODM: Faster

11) Compliance Responsibility

– OEM: Primarily buyer’s (define tests/standards; supplier executes).

– ODM: Shared; supplier provides baseline certifications.

12) Product Differentiation

– OEM: Strong (unique)

– ODM: Weaker (generic, need to negotiate for customization)

13) Suitable For

– OEM:

- Strong R&D team and design capabilities

- Pursue product uniqueness

- Innovation

- Long-term brand building and scaling

– ODM:

- Enter the market quickly

- Lack of R&D resources

- Limited budget

- Testing business ideas

Part 3. What Are the Advantages & Disadvantages of OEM

⭕ Pros of OEM

- You control all design details

You oversee every detail, from product design and materials to specifications, functionality, and intellectual property (IP).

- Stand out in the market

Customizing unique products for your brand instead of selling generic ones helps establish brand differentiation in the market.

Your design and core technology remain yours, making it harder for competitors to copy.

- Decide product quality and material

You decide what raw materials and components to use. This ensures consistent quality that matches your standards.

- Scalability for Growth

Once the design and tooling are in place, OEM production can scale up efficiently. It is good for long-term business expansion.

❌ Cons of OEM

- Higher upfront costs

It is a heavy investment to have your own team to develop samples, tooling, and molds at the beginning.

- Longer lead times

It takes more time to get your first order delivered from 0 to 1, which includes stages such as design, sampling, testing, and production.

- Greater buyer responsibility

You must provide clear specifications and strict quality standards for the products. Any gaps may lead to rework or delays.

- Strong supply chain management capabilities require

OEM projects require close monitoring of suppliers, production, and logistics. Strong management skills are necessary to keep things on track.

Need Help for Your Sourcing Project?

Let SVI Global find the right suppliers and manage your project.

We guarantee quality and on-time delivery!

Part 4. What Are the Advantages & Disadvantages of ODM

⭕ Pros of ODM

- Save on R&D

The supplier handles design and development, reducing the need for your own research team or equipment. This converts fixed R&D costs into manageable production expenses.

- Get to market faster

With pre-designed products available, you can select, customize slightly, and start selling in a short time.

- Lower risk for small buyers

ODM suppliers usually spread tooling and development costs across many clients, making it easier for smaller businesses to enter the market with low trial-and-error costs.

- Less technical expertise required

You don’t need an in-house design team or engineering knowledge. The supplier manages the technical side while you focus on marketing and sales.

❌ Cons of ODM

- Limited customization

You’re often working with the supplier’s base design. While you can adjust colors, logos, or packaging, deep customization is restricted.

- Less unique

ODM has multiple buyers who source and sell the same or similar products, not just you. It is harder to differentiate your brand.

- Thin profit margin

With more competitors offering similar items, you may get embroiled in price wars, undercutting prices and thereby affecting profitability.

- No IP control

The design belongs to the supplier, so you don’t own the intellectual property. If you switch factories, you can’t take the design with you.

- Less control over quality

The design and production process is often supplier-driven; you have less influence over material choices, testing standards, or long-term durability.

- Risk of Dependence on Supplier

Your product pipeline may rely heavily on the supplier’s innovation and continued support. If they stop producing, your business may be affected.

Part 5. FAQ about OEM and ODM

Q1. What are the key considerations when choosing OEM or ODM?

Weigh the following factors before opting for one model that suits your business.

- Product Design Expertise: Do you have a strong R&D team to complete product design?

- Investment Budget: Can you afford all the high initial costs? Is your project budget limited and do you wish to focus the costs mainly on production and marketing?

- Intellectual Property Ownership: Do you have unique product designs, patents or core algorithms? Are you willing to rely on an external partner for the core design and production of your product?

- Customization Requirements: Is the high degree of product differentiation crucial to your brand strategy? Or are small tweaks enough?

- Quality Control Needs: Do you have a team or resources to deeply monitor and manage the production quality of remote factories?

- Time to Market: Do you need to reduce lead times to quickly bring your product to market to seize market opportunities?

- Brand Strategy: Does your brand rely on innovation to lead the way or on marketing and distribution channels to win?

Q2. Which is better in quality, OEM or ODM?

The business model, OEM or ODM, does not determine the quality of the product. It relies more on the supplier’s quality management system itself, as well as the standards and requirements you put forward.

OEM gives you more control over materials and standards, while ODM puts more responsibility on the factory. Therefore, a reliable supplier is of the utmost importance. You need to take action to conduct a factory audit to make sure the supplier meets your needs.

Q3. Is ODM always cheaper than OEM?

The answer is not absolute.

For small-batch, fast-to-market, and market-testing products, ODM is undoubtedly a more “cost-effective” option as it significantly reduces your start-up capital and risks.

For core products that are mass-produced, planned for long-term production, and require continuous iteration, OEM is usually a more competitive option. Although the initial investment is high, in the long run, your control over costs and the supply chain will bring a greater overall cost advantage.

It is better to assess your project scale, long-term plans, and core requirements, calculate the overall investment and long-term returns of the project, and only then can you determine which model is for you.

Q4. If I sell on Amazon or direct to consumers, should I start with ODM?

Yes, for the vast majority of Amazon sellers, ODM is the lowest-risk, most cost-effective, and most common way to get started.

It allows you to test the market, launch rapidly, and minimize upfront risk. Once sales grow, you can consider OEM for unique, custom products.

Q5. When does it make sense to upgrade from ODM to OEM?

- When you need unique products to differentiate your brand

- When your products fail to meet customer needs

- When your scale and profits can support the initial investment

- When you want to build long-term brand equity

- When you need to strictly control costs and the supply chain

When you find that ODM can no longer support your growth and brand, it is time to consider OEM model. But remember that ODM and OEM are not opposing options.

Q6. Can the ODM factory support the design for my idea?

Some ODM factories have strong R&D teams and can create products from scratch based on a buyer’s idea. They help you from the prototype design, specification formulation, to production and after-sales support.

This deeper collaboration is more common for large, long-term clients or if the end product fits in the manufacturer’s portfolio.

However, it should be noted that in this mode, IP rights will not automatically belong to you. By default, the factory may have its completed design plan. You must clearly stipulate IP ownership in advance through the contract and sign a Non-Disclosure Agreement (NDA).

This kind of in-depth cooperation involving IP transfer is usually targeted at customers with stable orders and great potential for cooperation.

Part 6. How Can SVI Global Help You

Choosing an OEM path means taking on many moving parts, from defining product specs to ensuring quality at scale. That’s where SVI Global steps in. With 20+ years of experience and teams across Asia and Mexico, we support you at the OEM roadmap to reduce risks, save costs, and keep projects on track.

Here’s how we align our services with the OEM journey:

- BOM/Spec Freeze & DFM/DFX – Our product development and engineering teams help lock in critical-to-quality (CTQ) factors, packaging standards, and labeling requirements.

- Supplier Sourcing – With 1,000+ vetted factories across 9 countries, we can source the right partner, run capability checks, and perform light audits.

- Sampling & Validation – We guide clients through EVT → DVT → PVT stages, ensuring golden samples meet acceptance criteria before moving forward. Our in-house CPSC-certified lab adds extra assurance with testing and validation.

- Pilot Build – Our teams monitor yield rates and reliability checks while building out pre-shipment inspection plans.

- Mass Production (MP) – We oversee production management, inline and final inspections (AQL standards), and documentation packages, including certificates of compliance and test reports.

If you already have long-term suppliers, we’ll work within that structure, managing them under your standards while extending your capabilities. And if you’re looking to diversify, we can source and audit new suppliers without disruption.