What Should Product Final Inspections Include Before Shipping

- Date:

- Author: SVI Content Team

- Share:

Before your finished products leave the factory and head to the port, conducting a quality check is important to keep you at ease. A final inspection is your last chance to catch defects and verify quality. It is a safeguard that protects your shipments from mismatched requirements and maintains consistency across every batch.

Without further ado, let’s see the details about what final inspections are, what they cover in an examination, and how the process works.

Part 1. What Is Final Inspection in Manufacturing

Definition in Supply Chain

Final inspection, also called “pre-shipment inspection,” is the last thorough check of products before they are shipped out from the factory and delivered to the destination.

According to Deltek, “The overall product is measured against engineering, customer requirements and standards, and a final inspection report validates that all operations are complete and non-conformances resolved.”

During this stage, quality control teams will examine finished products’ quality, quantity, packaging, and labelling to ensure they are compliant with your demand and the standards of the importing country.

When Would It Be Taken?

Pre-shipment inspections are conducted when the production and packaging of the goods are nearly complete, typically when 80% of the products are ready for shipment. It’s an important part to make sure cargoes are free from defects and good to go during transportation.

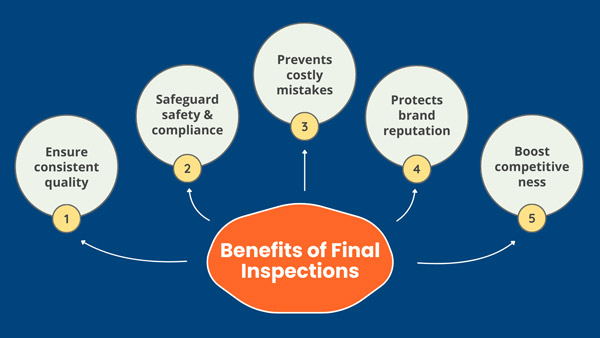

Why Is Product Final Inspection Important?

The purpose of the final inspection is to verify that manufactured goods meet your specifications, quality, safety, and compliance requirements before shipment.

The following are the benefits of final inspections:

- Ensure consistent quality.

By checking specifications and packaging before shipment, you can confirm that each batch matches agreed standards. It helps strengthen product reliability and durability across orders.

- Safeguard safety & compliance.

For industries tied to public safety (toys, electronics, automotive, medical), final inspections verify that products meet regulatory requirements and prevent unsafe goods from reaching the market, reducing both accident risks and potential legal exposure.

- Prevents costly mistakes.

Conducting the pre-shipment inspection can avoid shipment rejections and unexpected returns. By catching issues before products leave the factory, you will be able to the costs of after-sales services.

- Protects brand reputation.

Delivering high-quality products that meet customer expectations consistently not only reduces complaints, but importantly, helps build long-term trust and gain a brand credit that people can rely on.

- Boost competitiveness.

Having strong quality control measures to control product quality can create a competitive edge against rivals who overlook quality.

Part 2. What Final Inspections Should Cover

Just as you would double-check a gift or parcel before sending it off, you make sure the right item is inside, the wrapping or box is secure, and the address or tag is correct, and a final inspection does the same, but in a more thorough and systematic way. Here’s what inspectors focus on:

1. Quantity Verification – Is it the volume you ordered?

Inspectors confirm that the total number of finished cartons and units matches your purchase order. They also open sample cartons to check packed quantities against the packing list.

2. Workmanship & Defects – Do the products look and feel good?

The appearance and workmanship should be checked to identify any quality issues. Spot the visible defects like scratches, cracks, discoloration, blemishes, or any cosmetic defects, and observe the assembly quality like glue residues, uneven seams, or soldering that will affect the appearance quality.

3. Measurements & Specs – Do they match your requirements?

Using tools to measure the size, weight, materials, and components against engineering drawings or specification sheets. Finished products should align with your golden sample, and the measurements should fall within acceptable tolerance ranges.

4. Functionality – Can the products work without issues?

Functionality check is to confirm that products work as intended. The items should be able to operate, move, or perform properly.

For example, test a device by turning on/off or pressing buttons, check a toy by moving its parts, examining lights and sounds function, or inspect a shirt by checking zippers or snaps, etc.

5. Compliance – Do they meet safety standards?

Products should always be tested to meet the legal and safety requirements of your target market. This prevents you from customs rejections, recalls, and legal risks. By following relevant quality standards (ISO2859, ANSI/ASQC Z1.4, BS 6001, etc.), inspectors verify:

- Chemical safety: materials are within legal limits and free from restricted substances;

- Children’s products: no toxic paints, small detachable parts, or choking hazards;

- Electronics: insulation strength, grounding, and EMC (Electro Magnetic Compatibility) pre-checks to avoid shocks or interference.

6. Packaging & Labeling – Are they ready for safe delivery?

It’s crucial to check for proper packaging and accurate labeling to ensure products can withstand shipping and meet market requirements. These protect your cargoes in transit and lessen the risk of customs delays.

Make sure the shipments are with proper carton strength, size, sealing, and protective materials to prevent damage.

Meanwhile, review the labeling, from shipping marks, safety marks (CE, UL), to instructions, warnings and content lists are correctly placed.

7. Documentation Review & Record – Are the records accurate and complete?

Before starting the final inspection, inspectors will review previous inspection reports and test documentation. A review is able to help them understand issues happened before, identify areas to focus on, and maintain consistency across orders.

During the inspection, all findings should be carefully documented with notes and photos. Recording the ongoing inspection results can create a trackable quality history for the future.

Final Inspection Checklist for Your Products

| Aspect | What to Look for |

|---|---|

| Quantity Verification | ✔ Confirm the right number of units shipped matches the PO ✔ Sample cartons checked against packing list |

| Workmanship & Defects | ✔ Visible defects: scratches, dents, cracks, burr, spots, misalignment, discoloration; ✔ Assembly quality: glue residues, crooked parts, uneven seams, soldering quality |

| Measurements & Specs | ✔ Length, width, height, diameter, weight ✔ Materials used, components, etc. |

| Functionality | Operational checks and performance testing |

| Compliance | Guarantee products meet the targeted legal and safety requirements |

| Packaging & Labeling | ✔ Sender & recipient information ✔ Barcodes ✔ Model numbers ✔ Serial numbers ✔ Origin & destination ✔ Handling instructions & warnings ✔ Content description ✔ Safety mark (CE, UL) |

| Documentation Record | ✔ Review past inspection reports ✔ Record current non-conformities with photos ✔ Final signed report with pass/fail status |

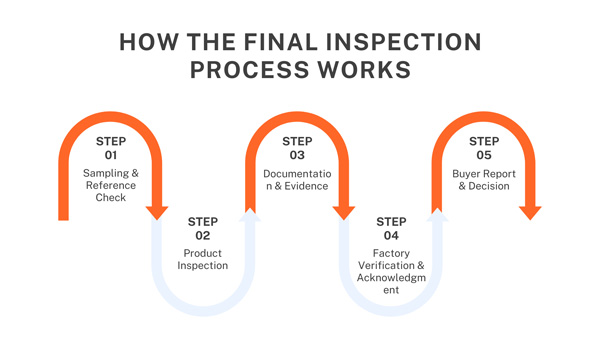

Part 3. How the Final Inspection Process Works

Step 1: Sampling & Reference Check

- Review product specifications, design, quality standards, and previous inspection reports.

- Select random cartons on-site at the warehouse or factory floor using AQL sampling standards (ISO 2859-1).

- Compare products with the buyer’s approved samples (golden sample) to ensure consistency.

Step 2: Product Inspection

- Check the workmanship, measurements, labeling, and packaging to ensure no errors like scratches, color mismatches, inaccurate labeling, or inappropriate packaging.

- Test the product functionality to ensure it works with no issues, including additional physical tests if required.

Step 3: Documentation & Evidence

- Record and photograph defects (Critical, major, and minor), packaging, and labeling for transparency.

- Findings are uploaded into a report in real-time or at day’s end.

Step 4: Factory Verification & Acknowledgment

- Non-conforming items are discussed with the factory on-site.

- Factory staff reviews and signs off on the inspection report to acknowledge the results.

Step 5: Buyer Report & Decision

- Importer receives a detailed final inspection report with defect breakdown and photos.

- Based on results, the importer decides whether to approve shipment, request rework, or hold the supplier accountable.

- Once everything passes inspection and no major issues remain, quality assurance gives a final sign-off, and the products can be packaged and shipped.

Need Help for Your Sourcing Project?

Let SVI Global find the right suppliers and manage your project.

We guarantee quality and on-time delivery!

Part 4. FAQ about Final Production Inspections

Q1. Who is responsible for the final product inspection?

Final inspections are carried out by qualified inspectors. These can be from the factory’s own QC team, independent third-party service providers, sourcing agents, or even your own local staff if available.

While factory QC teams can perform checks, the most reliable option is to hire a neutral third-party inspector who reports directly to you. This reduces bias and ensures you get an honest assessment of your goods.

Q2. Can I skip the inspection?

The inspection is not mandatory in most cases. Most importers include pre-shipment inspections because they help prevent defective products from reaching customers. Skipping them exposes you to hidden quality issues, unless you’ve worked with a factory you trust to deliver consistent quality for years.

In some cases, however, inspections are not optional. Certain countries legally require a Pre-Shipment Inspection (PSI) for specific goods. These governments aim to block unsafe or non-compliant goods from entering the market.

For example, in Indonesia, PSI is required for electronics, textiles and footwear, toys, food and beverage products, cosmetics, and scrap materials, according to the International Trade Administration.

Q3. How much does pre-shipment inspection cost and who pays for it?

Normally, inspection fees are paid by the importer. If you use a factory QC team or a sourcing agent, inspection costs may or may not be included in their service, so it’s important to clarify this in advance.

If you work with an independent inspection agency, you pay them directly. In cases where reimbursement is agreed with the supplier or supported by government programs, the agency can issue the invoice to them instead.

Q4. How can I get the most from final inspections?

Know how to make a successful inspection for your product quality.

- Be specific in your product specs and inspection checklist. Record and tick the boxes as the inspection goes on to avoid missing details.

- Review inspection reports carefully and combine with earlier checks (pre-production, in-process) for high-risk products.

- Document the inspection reports for tracking in the future.

- Partner with trained and certified inspectors who have sophisticated experience in specific industries.

- Keep an open communication to report product progress or issues accurately and immediately. It helps to address problems promptly.

Conclusion

A final inspection in manufacturing is a crucial step to ensure your shipments meet quality standards before leaving the supplier. It allows you to identify and address potential issues within your control, minimizing the risk of problems that are harder to manage later.

At SVI Global, we support buyers not only by managing local production but also by providing comprehensive quality assurance measures, including factory audit and ongoing quality inspections at every production stage. Our experienced, certified inspectors form a strong quality control team, ensuring that even when you are far from the production site, SVI Global acts as your reliable partner to safeguard product quality.