What Is Nearshoring in Supply Chain & Why Is It Popular

- Date:

- Author: SVI Content Team

- Share:

As global supply chains evolve, outsourcing manufacturing is no longer driven by cost alone. Complex trade environments, policy shifts, and market uncertainty are pushing companies to move manufacturing closer to home so they can respond faster to risks and customer demand.

But what is nearshoring, and when does it actually make sense for importers?

This article explains nearshoring in simple terms and shows how it benefits businesses and why it has become a growing trend in today’s global supply chains. Let’s get started.

Part 1. What Is Nearshoring: Definition

Meaning of Nearshoring

Nearshoring is a sourcing and outsourcing strategy where a company relocates production or services to neighboring or nearby countries rather than far-off regions.

The key idea behind nearshoring is geographical and cultural proximity. Suppliers are closer to the target market, usually share similar time zones, and often have fewer language or cultural barriers.

Most companies choose nearshore outsourcing to strike a balance between cost savings and better operational control, quality supervision and efficiency, especially when speed and coordination are of great importance.

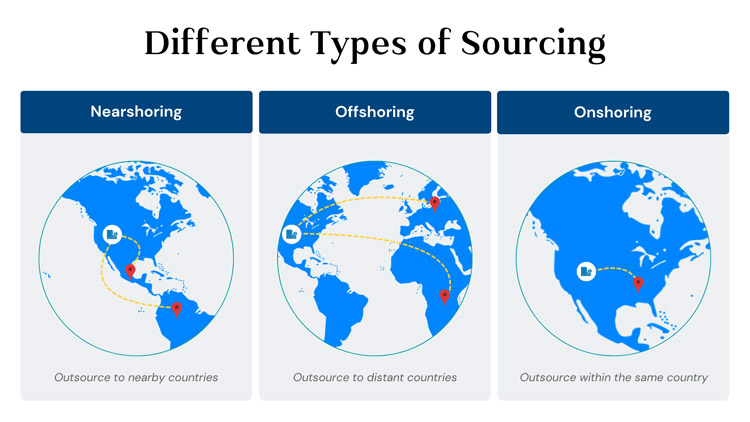

Nearshoring vs Offshoring vs Onshoring: Brief Contrast

– Nearshoring

Production is outsourced to adjacent countries, usually those sharing a border or within a short flight.

This strategy leverages lower costs than domestic manufacturing while maintaining better control than distant sourcing. It provides faster lead times and takes advantage of favorable regional trade agreements.

– Offshoring

Moving manufacturing activities to a region that is far away from the home country. This model is largely cost-driven as those countries have substantially cheaper labor costs.

There are large gaps in time distances, languages, cultures, and regulations. And this strategy exposes firms to unpredictable impacts from global supply chain volatility.

For U.S. companies, Asia has traditionally been the primary offshoring destination.

– Onshoring/reshoring

It is to manufacture products within the local market or bring production back to the home country.

Managing operations within national borders ensures maximum speed to market without time-zone friction or customs duties. This provides the highest level of control and compliance but requires higher labor and operating costs.

Part 2. Why Companies Choose Nearshoring

Businesses choose nearshoring mainly to gain speed, control, and flexibility without fully absorbing the high costs of domestic manufacturing.

Key Benefits of Nearshoring

1) Lower labor & shipping costs

Rather than manufacturing in developed countries, the nearshoring labor cost is cheaper than that of domestic workers. Meanwhile, shorter transportation distances can reduce shipping costs compared to shipping from offshore regions.

2) Faster response to market changes

By producing closer to the target market, shipments can be delivered within a few days instead of weeks or months, depending on the route.

The reduced transit times help firms bring products to market faster. Meanwhile, fewer worries about order adjustments and nearshoring support quicker reactions to shifts in consumer preferences or volume changes.

3) Great control of the whole project

Small time differences make it easier to solve issues in real time and keep projects moving without overnight delays. And the close location could let companies to visit facilities more often, audit processes and handle emergencies on-site, which provides stronger control.

4) Improved Coordination & Efficiency

Small time differences and similar cultures make communication with few barriers, and easier to schedule meetings to achieve real-time collaboration for most of the working hours.

5) Risk mitigation & supply chain resilience

By diversifying suppliers in nearby countries, it makes the supply chain more flexible and gives the choice to counter unexpected disruptions.

6) Potential tax benefits

Many nearshore partners are in countries that have favorable trade agreements, tariff reductions, or tax incentives with the home market.

7) Easier intellectual property protection

Similar legal and institutional frameworks can make it simpler to enforce contracts and protect IP compared with some distant locations.

Need Help for Your Sourcing Project?

Let SVI Global find the right suppliers and manage your project.

We guarantee quality and on-time delivery!

Part 3. Challenges of Nearshoring

There are always trade-offs in life, as well as in businesses.

1) Higher labor costs than Asian manufacturing hubs

While nearshoring is usually cheaper than onshoring, labor costs are often higher than in major Asian manufacturing centers, such as China, Vietnam. In many nearshoring countries, wages are also rising as demand increases.

2) More limited supplier options and flexibility

Compared with Asia, some nearshoring regions may have narrower material and process capabilities and only mature in a limited number of industries. This can restrict flexibility for some industries.

3) Exposure to trade and policy changes

Nearshoring relies on trade agreements and regional policies. Importers must closely monitor trade and regulatory changes globally.

A shift in tariffs, local labor laws, or trade preferences can quickly weaken the cost or compliance benefits that nearshoring was built on.

Part 4. Mexico: Popular Nearshoring Destinations in the United States

Mexico has emerged as a leading nearshoring destination due to its close proximity to the United States. Additionally, the country has implemented several initiatives recently to attract foreign investment, including free trade agreements and special economic zones.

One of the nearshore outsourcing advantages to Mexico is the reduction in transportation costs and shorter supply chains, which ultimately leads to faster delivery times and lower shipping expenses.

According to statistics from the Mexican Ministry of Economy, foreign direct investment attracted by Mexico during the first 9 months of 2025 increased by 14.5% compared to the previous period in 2024.

Mexico News Daily shows that manufacturing remains the top destination for foreign capital, attracting 37.1% of all investment flows in 2025. And investment in the first nine months of 2025 has already surpassed total figures for the entire previous year.

Despite the trade volatility in 2025, including new U.S. tariffs on multiple countries and selected goods from Mexico and Canada, Mexico remains a strong nearshoring option.

Under existing trade agreements, most goods can still move duty-free within North America. This makes outsourcing to Mexico still an attractive choice for companies relocating production.

Part 5. Is Nearshoring Well Fit for Your Business

Studies showed that most companies relocate their sourcing destination due to the cost factor. Cost is indeed an important factor, but rarely about price alone. The key is to learn how to balance cost, speed and control.

Nearshoring works well when:

- Are time-sensitive

Shorter transit times support faster replenishment and quicker responses to market demand.

- Need to protect margins beyond unit cost

Lower logistics, inventory, and delay-related costs can offset higher labor rates.

- Require stronger production control

Gain tighter oversight and more frequent on-site factory audits and quality inspections.

- Operate in volatile or fast-changing markets

Nearshoring is one way to improve supply chain flexibility when demand forecasts are uncertain.

Nearshoring may be less ideal when:

- Compete primarily on the lowest unit price

Ultra price-sensitive products often still favor Asia-based manufacturing.

- Rely on highly specialized supply chains

Some nearshoring regions lack mature ecosystems for certain industries or components.

Part 6. Latest trend in nearshoring in manufacturing

Post-pandemic supply chain

Disruptions exposed the risks of relying on a single sourcing location. As a result, many companies are diversifying production across regions to improve resilience rather than fully relocating.

Policy shifts and tariff uncertainty

Recent changes in U.S. trade policy, including higher tariffs on goods from multiple countries, have affected both nearshoring and offshoring decisions. Compared with offshoring, nearshoring has gained momentum because it reduces exposure to long-distance logistics risks while still controlling costs.

Nearshoring Examples

Some enterprises often adopt multi-sourcing strategies. Tesla is a clear example.

While China remains a major production base, Tesla has expanded manufacturing in Mexico to support the North American market. This diversification has not replaced China but complements it.

For small and mid-sized firms, the decision is more sensitive. With U.S.–China trade relations still uncertain and policy changes expected in the last few months of 2026, businesses need to assess future costs carefully.

How importers should evaluate options

Instead of focusing only on location, compare:

- Total landed cost in Asia (including potential tariff increases of 50% or more)

- Nearshoring or domestic production costs, including labor and logistics

- Delivery speed, inventory pressure, and risk exposure

- Diversify your supplier locations to several different countries to mitigate the risk.

How to Start Nearshoring with SVI Global

As nearshoring becomes more common, understanding what nearshoring is helps you start with the right perspective. Nearshoring is not only about cost. It also involves supply chain resilience, speed, decision efficiency, and political and trade considerations.

Before adopting it as a sourcing strategy, you need to assess your product, risk tolerance, and long-term goals.

For companies outsourcing to major manufacturing hubs in Asia or Mexico, SVI Global provides on-the-ground support. Our office presence is in 9 countries – U.S., China, Mexico, Vietnam, Thailand, Indonesia, Malaysia, Cambodia, and Korea. We can source manufacturing facilities both nearby and overseas. This flexibility enables you to choose between nearshoring and offshoring based on your specific requirements.